Ma mua, ua nīnau nā mea kūʻai aku i nā hoa hana mai RSM Technology Department e pili ana i ka titanium alloy.I kēia manawa, makemake wau e hōʻuluʻulu i nā ʻōlelo aʻe no ʻoe e pili ana i ka mea i hana ʻia me ka titanium alloy.Manaʻo wau hiki iā lākou ke kōkua iā ʻoe.

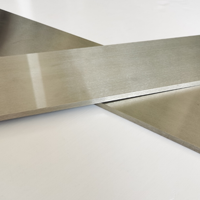

ʻO ka alloy Titanium kahi huila i hana ʻia me ka titanium a me nā mea ʻē aʻe.

ʻO Titanium kahi aniani heterogeneous homogeneous, me kahi helu heheʻe o 1720 ℃.Ke emi iho ka mahana ma mua o 882 ℃, loaʻa iā ia kahi ʻano hexagonal lattice paʻa, i kapa ʻia ʻo α Titanium;Loaʻa iā ia kahi hoʻolālā cubic i waena o ke kino ma luna o 882 ℃, i kapa ʻia ʻo β Titanium.I ka hoʻohana ʻana i nā ʻano like ʻole o nā hale ʻelua o ka titanium, ua hoʻohui ʻia nā mea hoʻohui kūpono e hoʻololi mālie i ka mahana hoʻololi o ka pae a me ka ʻike o ka pae e loaʻa ai nā alloys titanium me nā ʻano like ʻole.Ma ka lumi wela, ʻekolu ʻano o nā ʻano matrix nā huila titanium, a ua māhele pū ʻia nā huila titanium i ʻekolu mau ʻāpana: α Alloy(α+β) Alloy a me β Alloy.Ma Kina, ua hōʻike ʻia e TA, TC a me TB.

α titanium huila

ʻO ia ka α Single phase alloy i haku ʻia me ka hopena paʻa paʻa ʻo α Phase, hale paʻa, ʻoi aku ka pale ʻana o ka lole ma mua o ka titanium maʻemaʻe, ke kūpaʻa oxidation ikaika.Ma lalo o ka mahana o 500 ℃ ~ 600 ℃, mālama mau ia i kona ikaika a me ke kū'ē ʻana, akā ʻaʻole hiki ke hoʻoikaika ʻia e ka mālama wela, a ʻaʻole kiʻekiʻe ka ikaika o ka mahana wela.

β titanium huila

ʻO ia ka β ʻO ka mea hoʻokahi-phase alloy i haku ʻia me ka hopena paʻa paʻa i ʻoi aku ka ikaika me ka ʻole o ka mālama wela.Ma hope o ke kinai ʻana a me ka ʻelemakule, e hoʻoikaika hou ʻia ka alloy, a hiki i ka ikaika wela o ka lumi ke hiki i 1372 ~ 1666 MPa;Eia nō naʻe, ʻaʻole maikaʻi ka paʻa wela a ʻaʻole kūpono no ka hoʻohana ʻana i nā wela kiʻekiʻe.

α+β titanium huila

ʻO ia kahi hui pālua ʻelua me nā waiwai piha maikaʻi, paʻa paʻa maikaʻi, paʻakikī maikaʻi, plasticity a me nā waiwai deformation kiʻekiʻe.Hiki ke hoʻohana ʻia no ka hoʻoili ʻana i ke kaomi wela, ka hoʻopau ʻana a me ka ʻelemakule e hoʻoikaika ai i ka alloy.ʻO ka ikaika ma hope o ka mālama ʻana i ka wela ma kahi o 50% ~ 100% kiʻekiʻe ma mua o kēlā ma hope o ka annealing;ʻO ka ikaika wela kiʻekiʻe, hiki ke hana ma 400 ℃ ~ 500 ℃ no ka manawa lōʻihi, a ʻoi aku ka liʻiliʻi o kona kūpaʻa wela ma mua o ka α Titanium alloy.

Ma waena o nā huila titanium ʻekolu α Titanium alloys a me α+β Titanium alloy;Loaʻa i ka α Titanium alloy ka machinability maikaʻi loa, ʻo α+ P Titanium alloy ka lua, β Titanium alloy ʻilihune.α ʻO ke code o ka huila titanium ʻo TA, β ʻO ke code o ka huila titanium ʻo TB, α+β ʻO ke code o ka alloy titanium ʻo TC.

Hiki ke hoʻokaʻawale ʻia nā ʻāpana Titanium i nā ʻāpana wela, nā ʻāpana ikaika kiʻekiʻe, nā ʻāpana pale ʻino (titanium molybdenum, titanium palladium alloys, a me nā mea ʻē aʻe). ) e like me kā lākou noi.

Hoʻomaʻamaʻa wela: hiki i ka titanium alloy ke loaʻa i nā ʻano hana like ʻole a me ke ʻano ma o ka hoʻoponopono ʻana i ke kaʻina hana wela.Manaʻo nui ʻia ʻo ka microstructure equiaxed maikaʻi he plasticity maikaʻi, kūpaʻa wela a me ka ikaika luhi;He kiʻekiʻe ka ikaika o ka acicular, ka ikaika kolo a me ka paʻakikī o ka haki;ʻOi aku ka maikaʻi o ka hana piha ʻana o nā ʻiʻo equiaxed a me acicular

Ka manawa hoʻouna: Oct-26-2022